Raw materials for rubber industry: (PBR1220_SBR1502_NBR_SBS)

Polybutadiene rubber PBR PBR_1220 is the most important application of this product in the production of tires and rubber parts. It was one of the first types of elastomer or synthetic rubber that was invented. This polymer is very similar to natural rubber, i.e. polyisoprene. It is an elastomer and this rubber is suitable for applications dealing with low temperatures. Car tires are often made of polybutadiene copolymers. Belts, hoses, gaskets and other car parts are also made of polybutadiene because it shows better resistance to low temperatures than other polymers. Many polymers become brittle at low temperatures as a result of a phenomenon called glass transition.

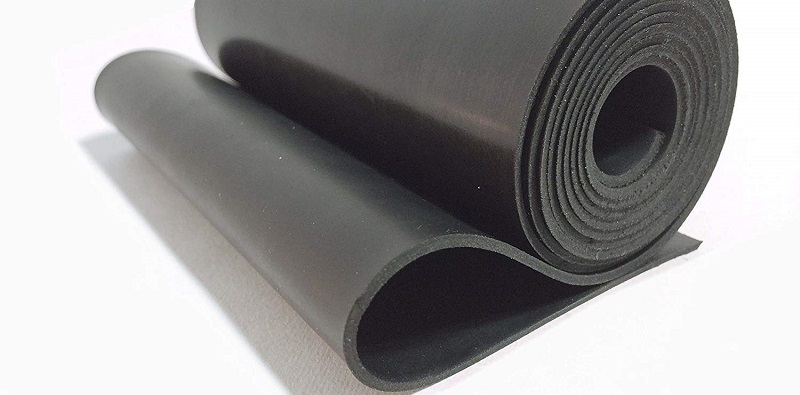

Hard rubber, called polystyrene, polybutadiene or rubber, is a copolymer containing polybutadiene. The application of Butadiene Rubber PBR, the high wear resistance and resistance to impact cracking of butadiene rubber has caused it to be used in most of the tire tread compounds. It is mostly used in the manufacture of tires for passenger cars, trucks and racing cars, as well as tire treads. It is also one of polybutadiene copolymers, butadiene rubber is used in the manufacture of shoes, belts and conveyor belts, rubber sponges, hoses and washers, and golf balls. In terms of price, this polymer is used to increase the concentration in industrial oils.

The main use of this polymer is an alternative to EPDM. It is used to viscose industrial oils.

Styrene Butadiene Rubber (SBR)

SBR1502 polymer is a synthetic rubber obtained from the combination of styrene and butadiene. These materials have good wear resistance. About 50% of car tires are made of different types of SBR. The ratio of styrene and butadiene affects the characteristics of this compound: with high styrene, the rubber will be harder. It is also used in building applications as a sealing and bonding agent behind renders. Styrene butadiene rubber can also be used to waterproof rooms or wet surfaces, a process in which rubber is applied to the entire surface (sometimes walls, floors and ceilings) to form a continuous, flawless waterproof bond.